These are the top 6 design considerations we would urge you to assess:

- Ball Proof

- Loads and deflection

- Panel sizes

- Slip resistance

- Fixing

- Treads and landings

This article refers specifically to the ball proof rating.

Open mesh flooring should be selected to provide a safe means of access for the expected pedestrian traffic whilst protecting people who could be below the flooring from falling objects. The designer or specifier should also consider the potential use of aids to the movement of materials and other objects (e.g., forklift trucks, pallet trolleys, sack barrows, skates etc.).

It is always best practice to refer to the grating manufacturer for full analysis of the impact of any vehicle or other non-pedestrian static or dynamic loads.

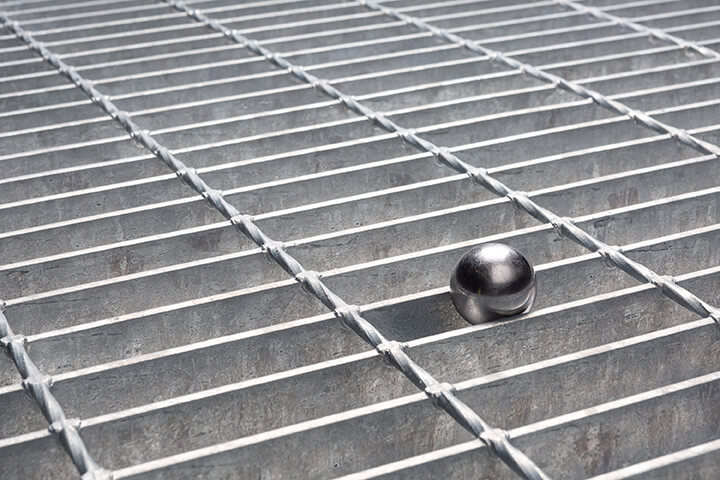

The way this type of flooring is identified is based on the size of object that will pass through the openings.

The smaller the opening, the smaller the object that can pass, thereby reducing the risk of impact and injury to those who may be working or passing below.

Therefore, the higher the volume of traffic or time spent beneath, the smaller the opening that should be selected.

Ball Proof Definition

Maximum permissible openings in open mesh grating are defined by 3 levels of ball proof – ball proof not required, 35mm ball proof and 20mm ball proof.

There are only 3 product options to choose from, with a simple guide on how to choose the best option for your needs:

20mm Ball Proof

To be used where a walkway is in constant use, traffic may pass regularly beneath or where people work below.

Used for platforms, walkways, landings, stairs and fire escapes. The smallest opening we offer and designed to not allow the passage of a 20mm diameter sphere.

35mm Ball Proof

To be used for access where a walkway is in occasional use, traffic may pass occasionally beneath and where there are no people working below.

Used for platforms, walkways, landings and stairs. Designed not to allow the passage of a 35mm diameter sphere.

Non Ball Proof, also known as Utility

To be used for walkways below head height and where people cannot pass underneath.

Used for access, walkways, shelving and fencing. Non-ball proof and has the widest opening.

Where ball proof is not required includes areas where floor panels are laid directly on or close to an existing closed element such as a floor or roof or where an alternate means of protection from falling objects is provided. In such cases the designer/ specifier should consider the comfort of the likely user.

Refer BS 4592-1:2006, Part 0, clause 5, which defines the maximum openings in terms of the passage of a 35 or 20mm diameter sphere – BALL PROOF REQUIREMENTS.

The purpose of this requirement of the standard is to provide a level of protection, from falling objects, to people who may be below the grating. The level of protection required should be clearly stated by the designer or specifier. Please note, if different levels or areas have differing levels of ball proof protection it is important to ensure these areas are clearly identified on the drawings. It is an inherent fact that the higher the level of ball proof the stronger the grating will be and capable of larger clear spans at any given bar size, therefore careful consideration should be given to the potential for a change of floor depth between areas with differing ball proof requirements.

To avoid confusion, the potential for mispositioning of flooring panels and the creation of differing flooring heights many designers/specifiers specify the whole project at the highest level of ball proofing.

Traditionally the grating industry has defined different flooring configurations by numerical definition of the pitch of load bars and the pitch of cross bars i.e., 25×5 41/100 is 5mm thick, 25mm deep load bars at 41mm centres with cross bars at 100mm centres. The industry is moving towards a definition based on the gratings ball proof level e.g., 25x 5 35BP the same size load bars and cross bars but arranged in a configuration to prevent the passage of a 35-diameter sphere and thereby in compliance with the latest UK and EU standards.