Fabrication

This interactive image will help you to understand the terminology we use for our products.

Click each touch point below to get a brief description of what we mean when we say each term.

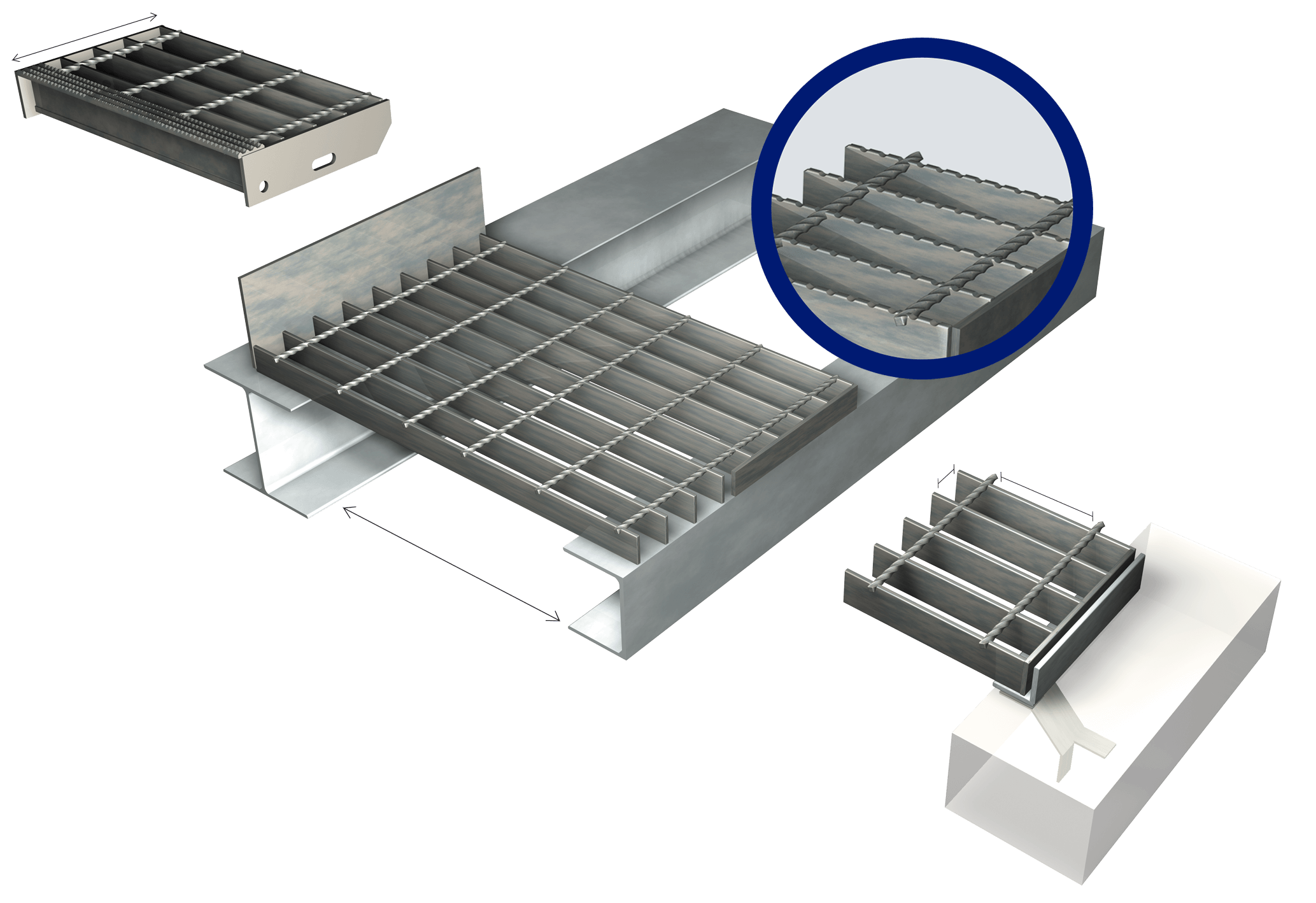

Width

The overall dimension of a flooring panel is measured perpendicular to the load bearing bars.

Width

The overall dimension of a flooring panel is measured perpendicular to the load bearing bars.

Nosing Bar

A slip-resistant member attached to the front of a stair tread or flooring panel.

Nosing Bar

A slip-resistant member attached to the front of a stair tread or flooring panel.

End Plate

A plate welded to a stair tread for fixing to a stringer.

End Plate

A plate welded to a stair tread for fixing to a stringer.

Toe Plate (Kick Plate)

A flat bar welded to a flooring panel projecting above the top of the load-bearing bars.

Toe Plate (Kick Plate)

A flat bar welded to a flooring panel projecting above the top of the load-bearing bars.

Length (Direction of Span)

The overall dimension of a flooring panel parallel with the load-bearing bars (this dimension is always referred to as ‘length’ even if it is shorter than the width).

Length (Direction of Span)

The overall dimension of a flooring panel parallel with the load-bearing bars (this dimension is always referred to as ‘length’ even if it is shorter than the width).

Binding Bar

A bar or section fixed to the edge of a flooring panel flush with the top of the load-bearing bars.

Binding Bar

A bar or section fixed to the edge of a flooring panel flush with the top of the load-bearing bars.

Pitch

The distance centre-to-centre of load bearing bars or centre-to-centre of transverse bars.

Pitch

The distance centre-to-centre of load bearing bars or centre-to-centre of transverse bars.

Transverse Bar

A member fixed perpendicular to the load-bearing bars.

Transverse Bar

A member fixed perpendicular to the load-bearing bars.

Load Bearing Bar

A load bearing member spanning between supports.

Load Bearing Bar

A load bearing member spanning between supports.

Curb Angle

A rolled steel angle (RSA) fixed to concrete to support flooring.

Curb Angle

A rolled steel angle (RSA) fixed to concrete to support flooring.

Bar Surface

There are two types of surface finish, which provide varying slip resistance to the flooring:

PLAIN

A smooth finish creating a slip-resistance to the flooring.

SERRATED

A serration formed in the top surface of the load-bearing bars gives enhanced slip resistance.

Bar Surface

There are two types of surface finish, which provide varying slip resistance to the flooring:

PLAIN

A smooth finish creating a slip-resistance to the flooring.

SERRATED

A serration formed in the top surface of the load-bearing bars gives enhanced slip resistance.